How much does a CO2 laser treatment cost

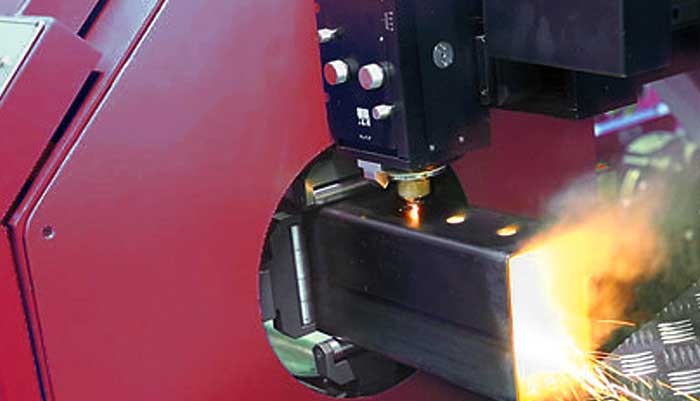

The other factor to keep in mind is that the traditional method of checking for bows and twists in the tube can take up to five or seven seconds before cutting commences. With the traditional means of touch sensing, you have to trade productivity for accuracy. Again, in the age of fiber laser cutting, this can seem like a lifetime, but working with tube is not as simple as working with sheet metal.

Gulf States Saw & Machinery Co., Inc. can help you develop new designs that improve aesthetics, increase functionality, and bring new products to market quicker.